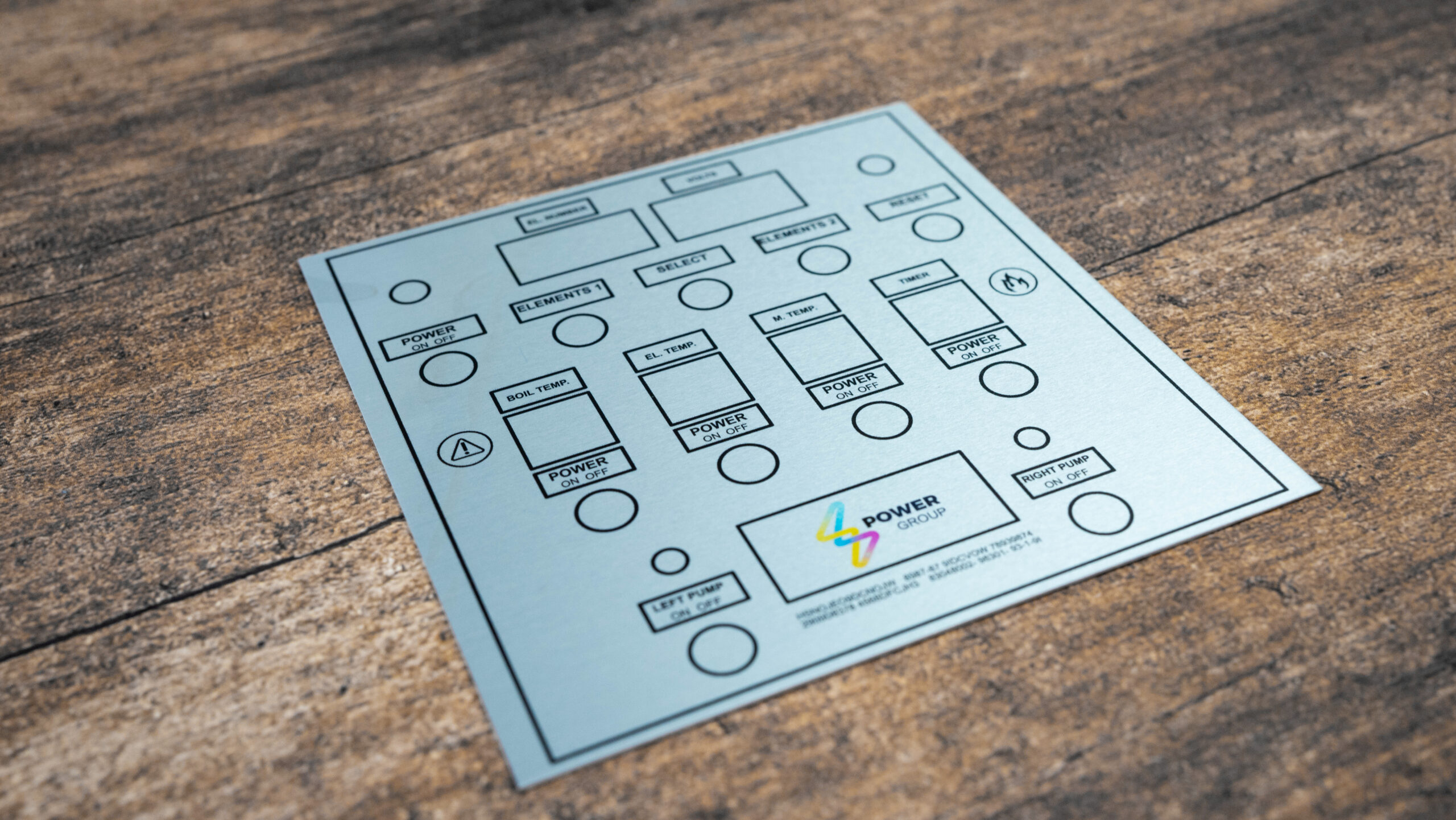

MODERN PLATES

MADE OF ANODIZED ALUMINUM

Offer

Explore applications for anodized aluminum plaques

Anodized plates are used wherever durability and product quality are required, such as: equipment nameplates, control panels, descriptive panels, building and room markings, museum boards, warehouse markings, but also premium business cards, rulers, dedication plates in the jewelry industry, or watch dials.

How to order ?

Don’t delay! Order aluminum plaques now. Trust us as a partner to provide you with solutions you can count on.

Who are we?

PRINTING TECHNOLOGY IN ANODIZED ALUMINUM

Inkjet printing technology in anodized aluminum offers great opportunities for the use of this material in many industries. Post-anodized aluminum with a flat surface is printed with any graphics using the digital printing method, and then subjected to a sealing bath. The technology makes it possible to obtain indestructible printing resistant to scratches and chemicals. It competes with engraving and other printing methods, which do not provide such durability and precision. The special ink is deposited in the pores of the oxide coating, so precise printing can be achieved, the accuracy of which can be seen even with a magnifying glass.

Do you want to start your own production?

Order a technology package for printing in anodized aluminum and redirect to the page about printing technology in anodized aluminum.

USE OF ANODIZED ALUMINUM

Post-anodized aluminum is used where parts are exposed to atmospheric agents or aggressive environments of acid and moisture that cause corrosion. Due to the high hardness of the glaze, the details are also used for parts exposed to abrasive factors. A distinctive possibility offered by anodizing technology is the coloring of the details. This gives a very aesthetic appearance to the details with the possibility of personalization according to the needs. Dyed parts are used as parts of machine and equipment housings, furniture, as control panels and everyday gadgets. The possibility of coloring the oxide coating gives great potential for future applications of anodized aluminum